wholesale Small Moq Transfer Cooling Oil Cooler Heat Exchange Tube Energy Saving And High Efficiency air compressor aftercooler

- Information

Product Description

Intercooler:

Most industrial compressors currently in operation are multi-stage designs. In order to optimize the cost of compressed gas, it is common to use multi-stage industrial compressors. When the air compressor compresses air, heat is generated, which causes the air

to expand, and it is necessary to increase the HP for further air compression. It is suitable for the first and second stages of a multi-stage air compressor. The function of the compressor intercooler is to provide cooler, drier, and denser air for the next stage of compression.

Aftercooler:

The cooler is followed by a heat exchanger that removes heat from the compressed air. The most common compressor after the cooler uses cold ambient air or cold water to remove heat, which also effectively removes moisture from the compressed air.

Oil cooler:

The purpose of the engine oil cooler is to allow the engine's cooling system to remove excess heat from the oil. These types of coolers are usually of the water-to-oil type of heat exchanger. ... The oil then flows through the tubes of the cooler while the engine coolant flows around the tubes

Most industrial compressors currently in operation are multi-stage designs. In order to optimize the cost of compressed gas, it is common to use multi-stage industrial compressors. When the air compressor compresses air, heat is generated, which causes the air

to expand, and it is necessary to increase the HP for further air compression. It is suitable for the first and second stages of a multi-stage air compressor. The function of the compressor intercooler is to provide cooler, drier, and denser air for the next stage of compression.

Aftercooler:

The cooler is followed by a heat exchanger that removes heat from the compressed air. The most common compressor after the cooler uses cold ambient air or cold water to remove heat, which also effectively removes moisture from the compressed air.

Oil cooler:

The purpose of the engine oil cooler is to allow the engine's cooling system to remove excess heat from the oil. These types of coolers are usually of the water-to-oil type of heat exchanger. ... The oil then flows through the tubes of the cooler while the engine coolant flows around the tubes

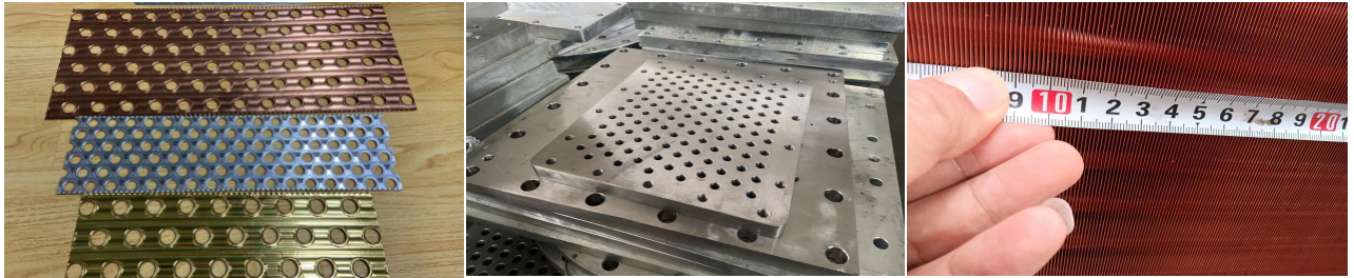

Product Configuration

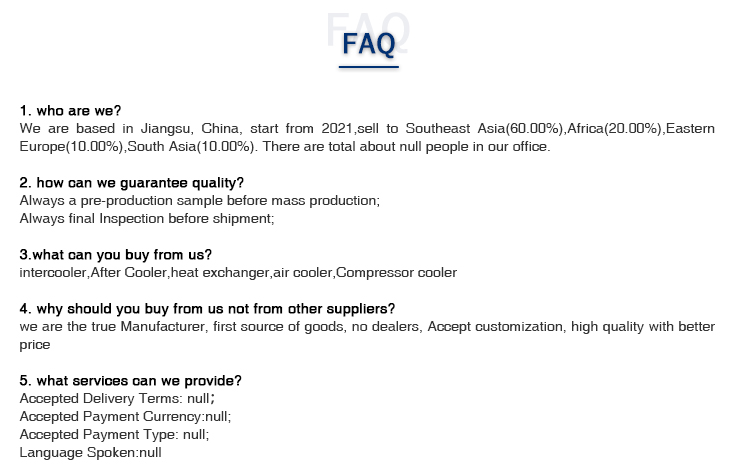

Fin Tubesheet Assembly

Fin Tubesheet Assembly

Specification

item | value |

Applicable Industries | Manufacturing Plant, Retail, Energy & Mining, Other, electric, textile mill, electric industry |

Showroom Location | None |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Warranty of core components | 1 Year |

Core Components | cooling fin, end cap, heat exchange tube |

Condition | New |

Place of Origin | China |

Brand Name | HAOLINJIAN |

Structure | Tube Heat Exchanger |

Weight | 100KG |

Warranty | 1 Year |

Key Selling Points | Energy saving and high efficiency |

Product Name | Heat Exchanger for Air Compressor |

Keyword | Oil Cooler After Cooler Inter Cooler |

Feature | Quick Cool |

Application | Heat Transfer Cooling |

Tube material | copper brass stainless steel |

Function | High Efficient Heat Transfer |

Brand | OEM |

Port | Shanghai |

Package | Wooden Case |

Supply ability | 2000 units per month |

Company Profile

Hubei Highlighting Thermal Equipment Co., LTD is one of professional high-tech enterprises, engaging in heat exchanger research and development, design, manufacturing, sales and after-sales service .The leading products are for air cooler, oil cooler, water cooler, heater, evaporator and condenser, covering heat exchanges of mediums with air-water, air-oil, water-oil, oil, gas-liquid, liquid-liquid , and can design and manufacture more than two kinds of medium heat exchange products.Products are widely used in air compressor, air separation /oxygen production, power station, locomotive, heavy machinery, ships, diesel engine, environmental protection and energy saving, waste energy recovery industrial areas.

Hubei Highlighting Thermal Equipment Co., LTD is one of professional high-tech enterprises, engaging in heat exchanger research and development, design, manufacturing, sales and after-sales service .The leading products are for air cooler, oil cooler, water cooler, heater, evaporator and condenser, covering heat exchanges of mediums with air-water, air-oil, water-oil, oil, gas-liquid, liquid-liquid , and can design and manufacture more than two kinds of medium heat exchange products.Products are widely used in air compressor, air separation /oxygen production, power station, locomotive, heavy machinery, ships, diesel engine, environmental protection and energy saving, waste energy recovery industrial areas.

Get the latest price? We'll respond as soon as possible(within 12 hours)